Perfect for

Laboratories

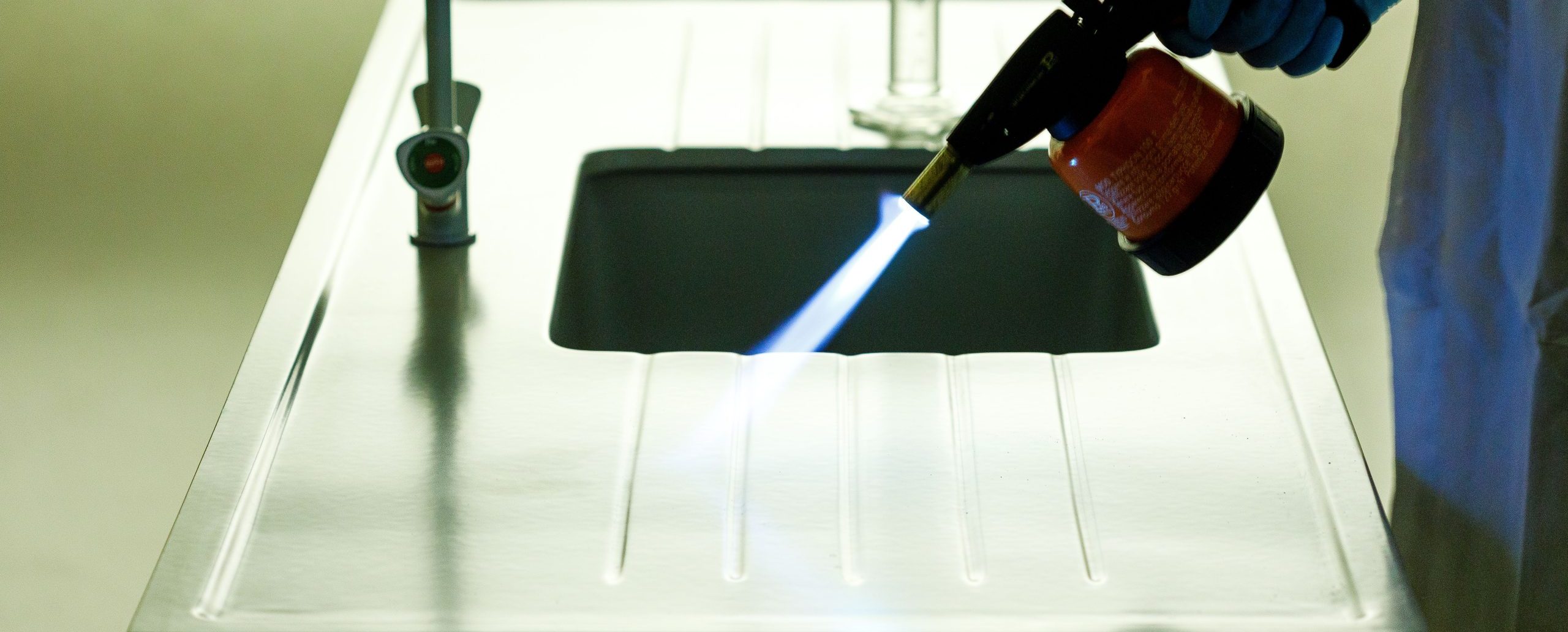

Acids & Basics

resistant

Scratch resistant

Heat – Proof

Easy to clean

Frost – Proof