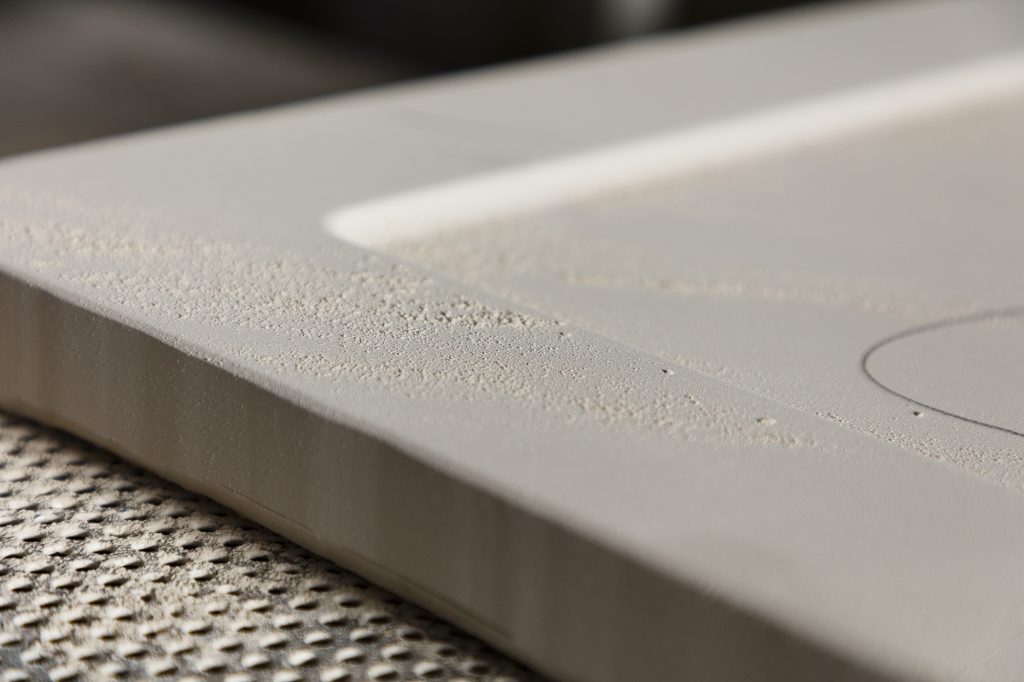

Our high-quality standards begin with precise control of every detail, starting from the initial steps of the production process. As a result, the imperfect semi-finished products are rejected.

However, our material can be recycled and so the rejected semi-finished products are grounded into powder and reintroduced in the production process.